BRICK

Most people have NO idea how important brick making was to Charleston and the United States.

We had some of the best clays in the world right here. Our brick went

all over the Eastern Seaboard, from NY, NJ, and Philadelphia for housing

projects. From Chicago to Florida for homes and buildings of all kinds.

Henry Ford bought all the brick we could make, especially

fire brick. Our brick went to build the Kraft Cheese Co., the Eastman

Kodak company, the Cincinnati Airport, the Cincinnati Kroger Warehouse,

the Ponce De Leon Hotel in Roanoke Va, not to mention thousands of homes

and buildings, like the Daniel Boone Hotel locally. We had 3

main plants: The Elk 2 Mile plant that was still operating when I was

young, the Kanawha 2 Mile plant, which had an overhead conveyor that

crossed 7th Ave, and the Elkland Brick Company which was located where

the entrance to Coonskin Park is today. They mostly made important fire

brick for the thousands of companies like Ford who needed it for their

furnaces.

|

WV Brick Company

(West Virginia Clay Products - Charleston Fire Brick Company)

| Homer

Wiseman owned the WV Brick Company for many years; then it was

passed on to Clyde Wiseman and Claude Wiseman. The made face

brick and fire brick, but eventually they couldnt produce both in

enough quanity, so they gave the fire brick business to the Elkland

company just up the river at what is now Coonskin Park. They also

had

a plant in Barboursville. The Elk Two Mile plant was liquidated in

about 1970. The plant property covered the mountain which

now includes Northgate Park. |

| Along the Elk River on Barlow Drive is

a complex that once had several names and in fact, opened and closed

several times over it's history. We just called it "the

old brick plant". I can remember hauling as many "rejected"

brick as my red wagon could carry from this plant to Smith street.

The load was so heavy that by the time I got home, all the rubber

tires had come off the wagon. The photo above shows part of

the old original conveyor belt that ran from the plant across the

road, then up the hill to where the clay mine entrance was.

Just above that is a nice sized pond. |

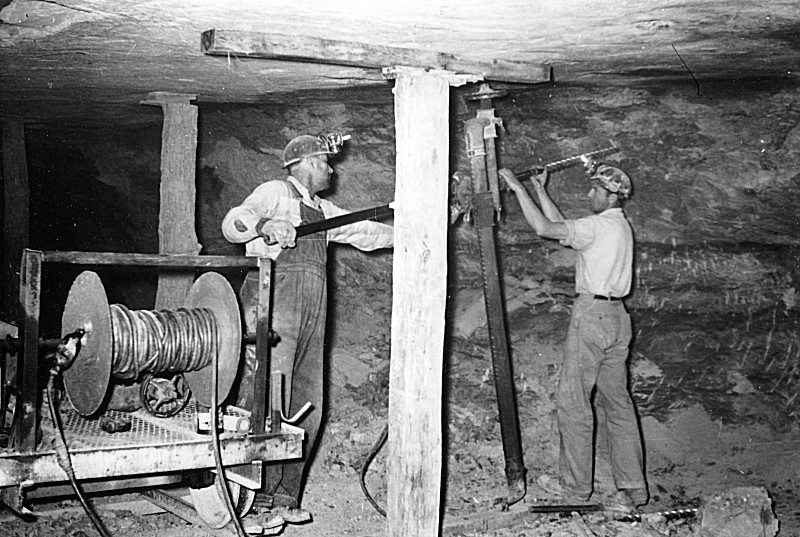

LETS TAKE A LOOK AT THIS PLANT IN THE

LATE 40S, STARTING WITH THE MINE

| The old clay mine entrance. I

have been here many times and have actually gone inside for some distance

before the water and obvious slate fall turned me around. It

now has a metal gate blocking the entrance and is hard to get to. |

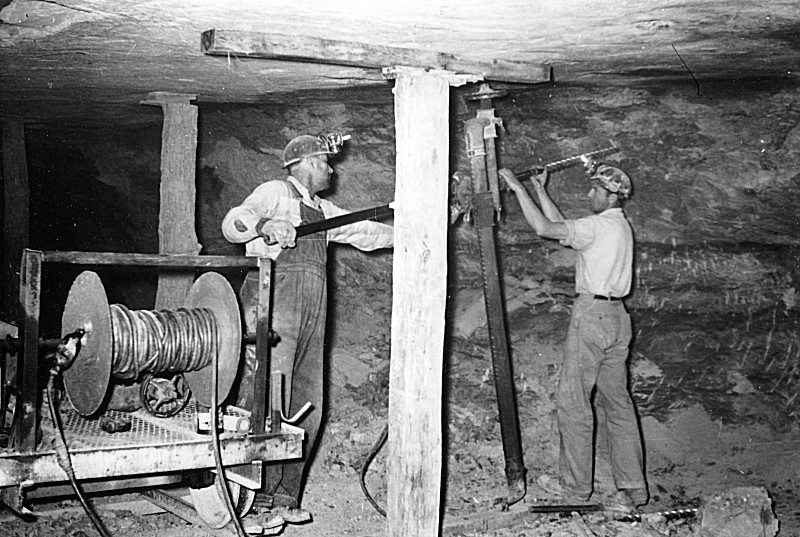

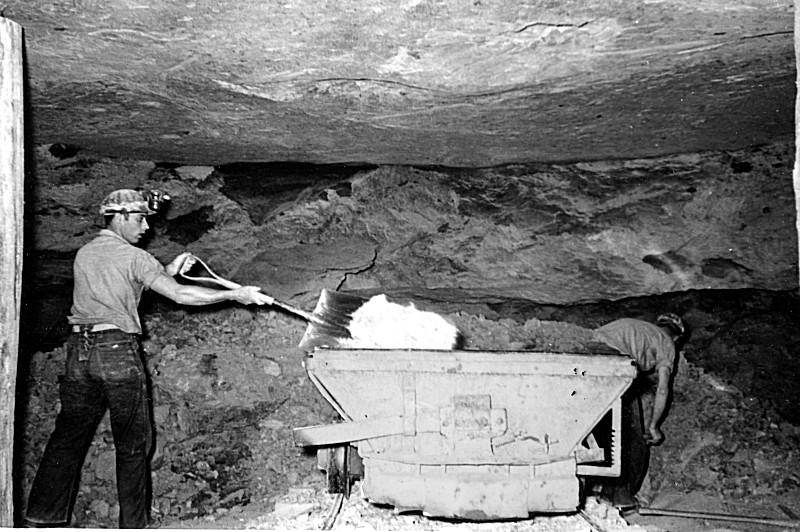

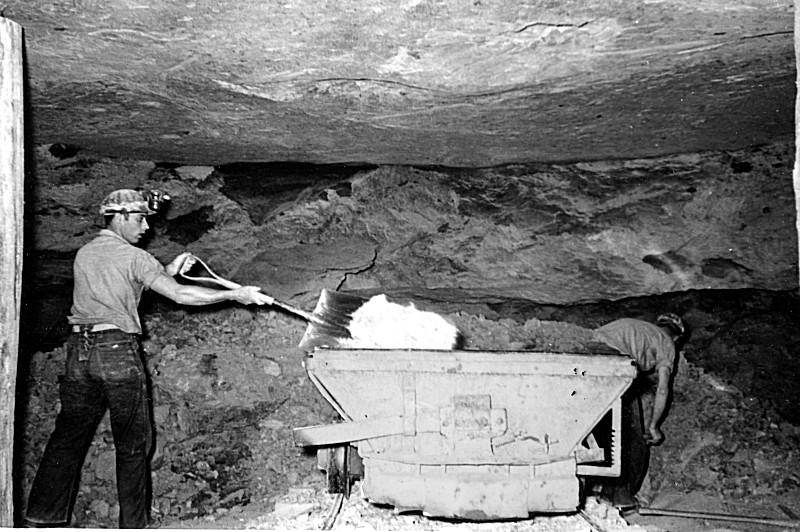

Men drilling the clay. Other

than not being as dirty, clay mining is pretty much just like coal

mining.

Few clay mines around here were as

automated as the coal mines at the time.

Even in the late 40s, Mules were still used

here for their cost effectiveness.

The clay miners. One might be your father or grandfather,

especially if you lived near the plant.

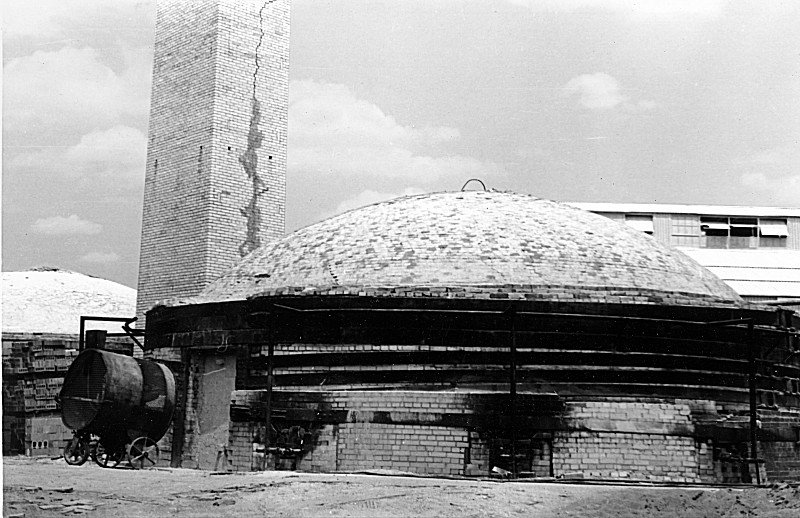

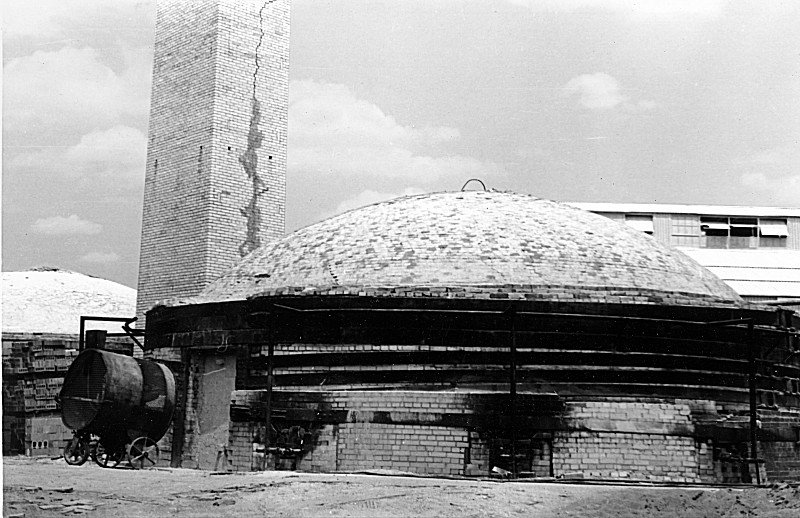

This is one of the kilns where the brick was baked.

Most brick made here was fire brick shipped out of state.

Checking the "glory hole" for heat.

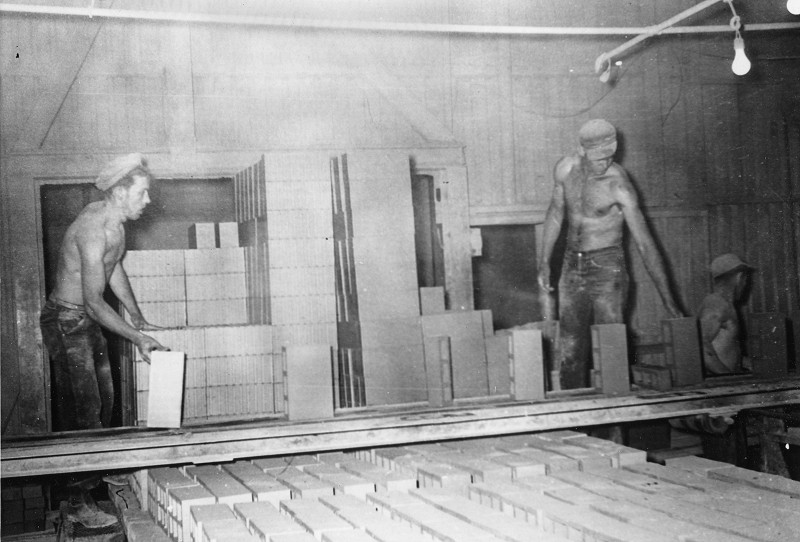

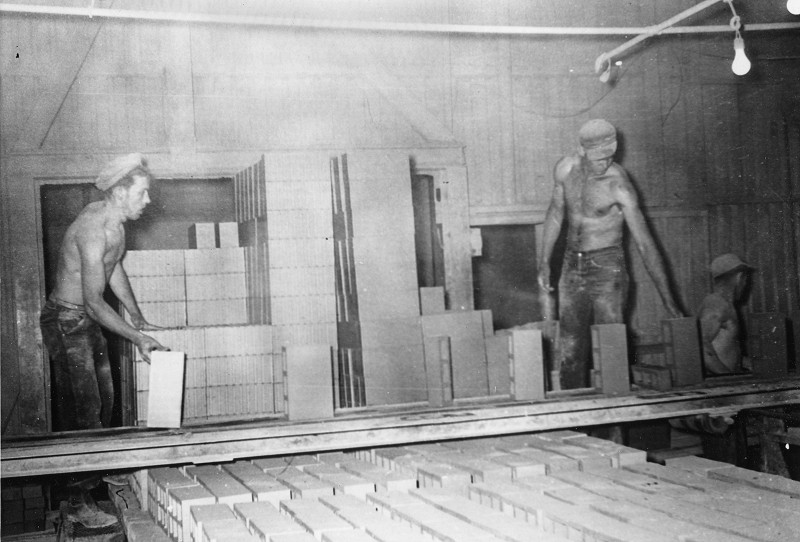

Working with small block here in a very hot environment.

I doubt OSHA would approve today.

Hardened block ready to transport.

The green line shows the old conveyor route up the

hill to the mine. You can also see the pond just above it.

This is a shot of the pond that I took a couple of

years ago.

This is my friend Danny Davidson on one of his many trips to the old clay mine entrance.

If you're the least bit interested in learning more

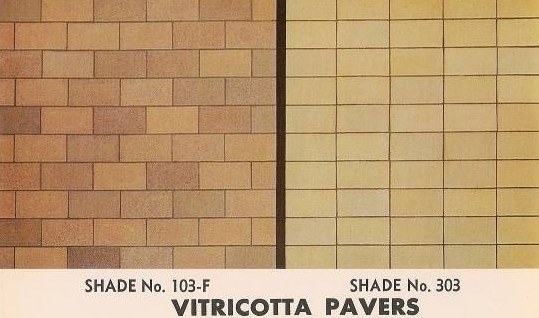

about the local clay mines.... ELKLAND FIRE BRICK COMPANY 1927 Later Charleston Vitreous Clay Products Company.. specializing in glazed building tiles

Henry

Ford got much of his materials to build cars and factories from West

Virginia. He bought coal and coal mines to heat his furnaces and

to make steel. He also needed brick, both to build his

factories and to build his ovens. Most of that brick came from

right here on the Elk River, because it was considered the finest clay

of its kind. The fire brick was of exceptional quality, and so he

purchased the entire production.

|

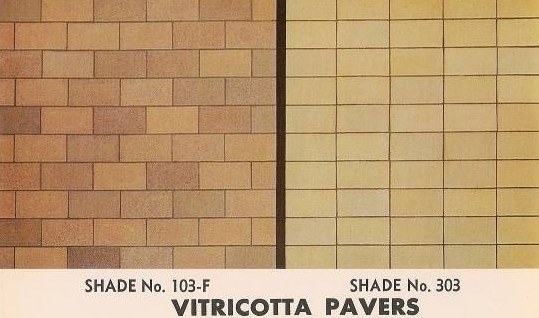

This

is a color sample of the tiles they made. If you look around

Charleston and beyond, you will see this product in just about

every old school and office building built here in the last 100 years.

They also made white and blue wall and floor tiles, fire brick, and 10 colors of regular building brick.

|

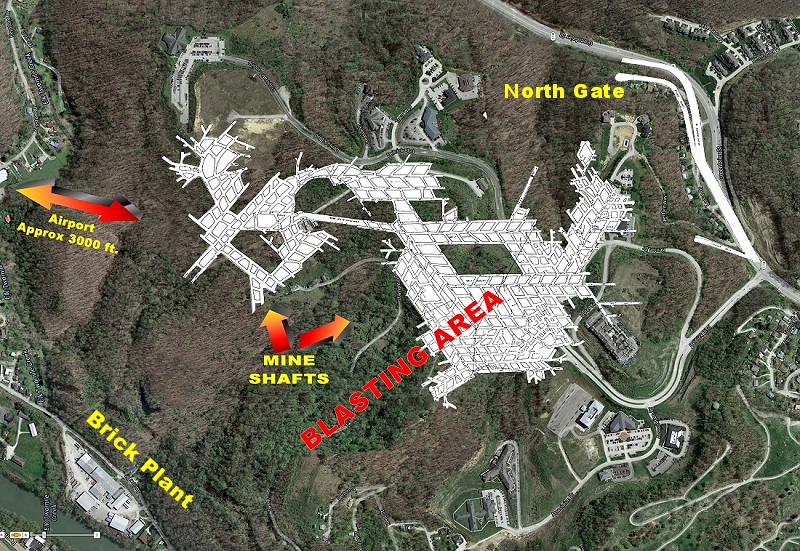

The

photos above were taken at the old Elkland mine area in 2015.

Shafts, bits of machinery and broken tile still litter the

landscape. Most of Coonskin Park sits atop a large labyrinth of

clay mine shafts.

|

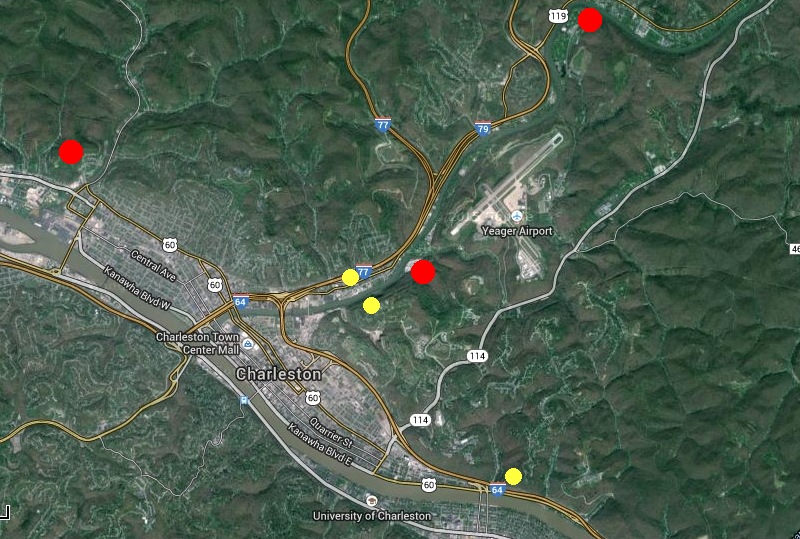

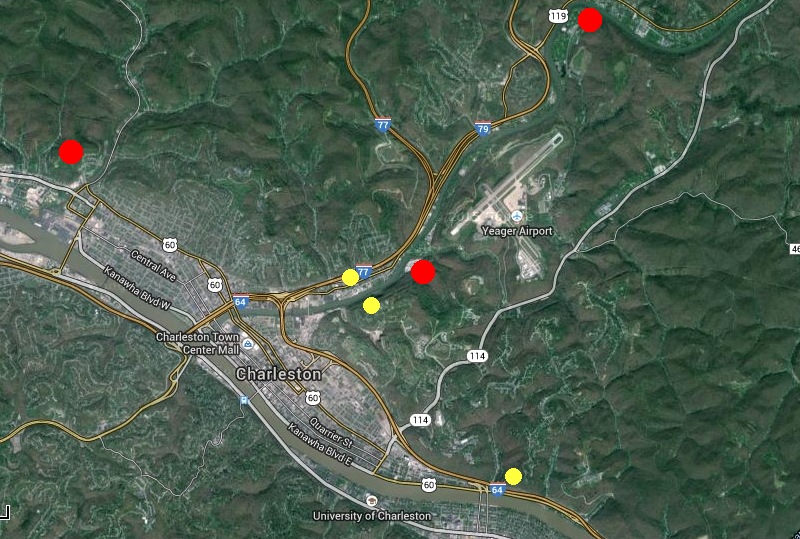

This map shows the main clay mines in red, while the yellow represents clay surface operations.

THE RALPH BARD STORY Ralph Austin Bard (July 29, 1884 – April 5, 1975) was a Chicago

financier. His son wrote the following:

In 1939, my father asked me if I

would like to help rescue a difficult investment he and others had

made in a tile and brick plant in Charleston, West Virginia, which was losing $25,000

per month. So we moved east. After observing operations for a month,

I decided that I understood the business and fired the plant manager,

the sales manager and several others, and took over all their jobs.

All losses stopped, but my wife and family saw little of me for two

years, and I became very unpopular with the CIO. and the United Mine

Workers. At one time, two C.I.O. agents tried to push me into

a hot kiln and later a miner arranged to drop a large chunk of clay

on my head in our deep mine. In 1941 with one more child, a

son, we left Charleston Clay Products, leaving the company in good

hands.

World War II changed all our lives. My father, Ralph A. Bard was

Assistant Secretary of the Navy (later Undersecretary) and because

of this I didn't want to accept a commission in the armed services,

but I did want to participate. I enlisted in the Marine Corps as a

private and went to boot camp at Parris Island....

After the war, I figured it was a

perfect time to be self-employed. Rawleigh Warner, Jr. (1944) and

I formed our own company, Warner-Bard, and had an interesting time

finding financial backing to launch people with new ideas and inventions,

some good and some terrible. Rawleigh left to work in the oil business

and, later, became Chairman and C.E.O. of Mobil Oil. In Barrington

Hills, outside of Chicago, we added another daughter to our family.

I visited Charleston Clay Products and was surprised to find large

shipments of tile going to Toronto - too far for us to ship before

the war. I went to Toronto to see why, and was amazed at the enormous

growth and opportunities there. Oil had been discovered in 1946, and

there was a ferment of oil and mining exploration. I was fortunate

to meet some of the mining, oil and banking leaders of Canada and,

eventually, organized an investment company with backing from some

of them and U.S. investors. Pretty exciting times ! |

More... From the West Virginia Geological and

Economic Survey, 1905

| In Kanawha county, in 1905, there were

three brick plants, manufacturing building and paving brick in the

city of Charleston: The W. Va. Clay Products Company, The Standard

Brick Company and The Kanawha Brick Company. Most would continue to

be worked into at least the 1950s. |

West Virginia Clay Products Company.

| "The plant of this company was built

near the close of the year 1902, two and one-half miles west of Charleston

on the Kanawha & Michigan railroad. The plant was a very substantial

one, with a large equipment of machinery, housed in large and well

constructed buildings. The cars were hauled from the mine by electric

trolley and the buildings lighted by electricity. It was one of the

most expensive plants in the State, but was destroyed by fire in the

fall of 1904 and has not been rebuilt. It manufactured fire brick,

building brick and a very high quality of paving block. The destruction

of the plant was a great loss to the brick industry of the State. |

West Virginia Clay Products Company

Mine Two This plant was formerly the Charleston

Fire Brick Company, and on pages 231-233 of Vol. Ill, West Virginia

Geological Survey, the following description is given:

"The plant of this company is

located up Elk river two miles from Charleston at Two Mile creek station

on the Coal & Coke railroad. It is one of the old brick yards

of the Charleston region, and has been used from time to time for

the manufacture of fire brick, but it has been idle since 1901. During

that year 1,500,000 fire brick were made for the coke ovens of the

*Kay Coal Company.

"The capacity of the plant is

25,000 bricks a day. The plant is equipped for the manufacture of

stiff-mud building brick, though none has been made for some years.

The equipment consists of a nine-foot dry pan, six-foot wooden pug

mill, Bucyrus auger of 30,000 capacity, Eagle repress. The building

bricks were dried in minetrack tunnel drier heated by fires below.

The fire brick were dried on a heated floor large enough to hold 10,000

brick. The building brick were burned in one up-draft kiln, and the

fire brick in two round down-draft kilns, 26 feet in diameter, drawing

into one stack.

"The river clay from a ten-foot

pit near the mill was used for building brick. The fire brick were

made from a mixture of one third flint clay and about two-thirds plastic

clay from the mine on the hill back of the plant.

"Clay Mine.—The clay

is worked in an open pit one mile and a half from the plant on Elk,

and 180 feet above the level of the plant. This mine could be reached

by wagon road and the clay was formerly hauled to the plant by this

route. Later a track was built from the mine around the hill to an

incline by cable and across the railroad on raised trestle to be dumped

at the mill. This track is now in bad repair but could be renewed

at no great cost.

"Some of the best fire brick

in the State were made for a number of years on Elk river, just above

Charleston, but at the present time no fire brick are made in this

vicinity. Near Charleston are located some deposits of fire clay equal

to the best in the State, and to be favorably compared with standard

fire clays of the Eastern states. These shales and clays make paving

brick of the highest quality, and the deposits are almost unlimited.

They burn both buff and red, making fine grades of pressed and ornamental

building brick. Here also occur fine grained clays adapted to manufacture

of pressed brick and tile, also good stoneware clays.

*Vol. Ill W. Va. Geological Survey,

1905. |

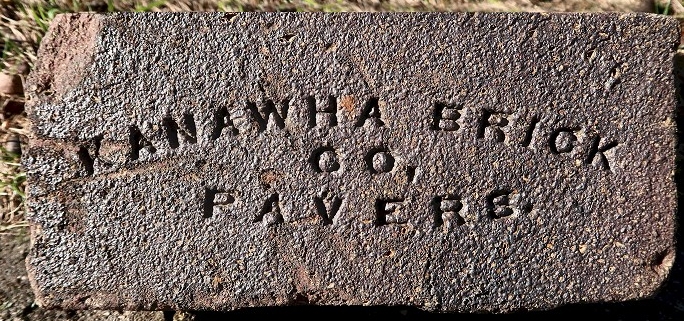

Kanawha Brick Company

Section 1 was 1.3 Miles east of Charleston, at Mine of Kanawha Brick

Company.

Section 2 was on the Elk River, the plant being at 1600 Penn. Ave.

"At the plant of this company,

one mile east of town on the Kanawha river, ten feet of river clay

is worked, as well as the hard clay from the hills above. The equipment

of the plant has been described in the preceding chapter with a description

of the hillside clays. The river clay has been used since 1897 in

the manufacture of red building brick and is burned in three up-draft

kilns.

"This company has another yard

on Elk river, one mile from Charleston, which was started by Mr. Isaacs

seventeen years ago. The clay is ground in a Potts crusher, tempered

in a twelve-foot pug mill and molded on an auger machine of 40,000

capacity, making 25,000 brick daily. The brick are dried in an eight-track

steam tunnel drier, holding 72 cars, with 45,000 capacity. The brick

are burned in one down-draft kiln, 28 feet in diameter, holding 60,000,

and three updraft kilns, 21 arch, holding 360,000 each, and burned

with gas.

"The river clay is 15 feet thick

in this pit and is hauled in cars by cable to the plant. The first

paving brick probably used in the United States were made from the

Kanawha Valley river clays at a point further down the river, by Mr.

Isaacs.

"In the Charleston region

there have been a number of brick plants in operation at various times,

a number of which have been unsuccessful on account of poor business

management rather than on account of the quality of the clays. The

first brick paved street in the United States was laid in Charleston

in 1872. One block of Summers street, nearest the Kanawha river, was

paved with brick set on sand, with a substructure of planks dipped

in tar and also resting on sand. This block is still in use, and the

street at this day is in very fair condition. For a number of years

after that date, the Charleston brick was shipped into Ohio, and the

first brick paved street in Columbus in the early1880's was laid with

the Charleston brick, set on tarred planks.

"With the opening of the paving

industry in Ohio, the sale of Charleston brick was confined to the

State, and in later years they were used mainly for local trade, very

few paving brick being shipped away. At the present time no paving

brick are made at Charleston.

This clay is also found on the other creek valleys near Charleston,

and on Ferry Branch on the south side of the Kanawha river, opposite

the mouth of Elk river, where the clay is exposed along the road leading

from Kanawha river to Sugar Camp creek of Davis creek, and is about

10 feet thick, 120 feet under the Ames limestone horizon.

|

The Standard Brick Company.

Clay was once mined near the mouth of

the Kanawha Two Mile Creek by the Kanawha and New River Fire Brick

Company, on the west side of the Sissonville road.

The Kanawha and New River Fire Brick

Company once manufactured brick in Charleston, but the plant is now

abandoned, as it was destroyed by fire in 1904, and has been rebuilt

as the Standard Brick Company. The following is a short description

of the original plant and mine given in Vol. IIl, pages 229-231, W.

Va. Geological Survey, 1905:

"The plant of this company was built

near the close of the year 1902, two and one-half miles west of Charleston

on the Kanawha & Michigan railroad. The plant was a very substantial

one, with a large equipment of machinery, housed in large and well

constructed buildings. The cars were hauled from the mine by electric

trolley and the buildings lighted by electricity. It was one of the

most expensive plants in the State, but was destroyed by fire in the

fall of 1904 and has not been rebuilt. It manufactured fire brick,

building brick and a very high quality of paving block. The destruction

of the plant was a great loss to the brick industry of the State.

"The equipment consisted of two

nine-foot Stevenson dry pans, one Martin wet pan, twelve-foot plug

mill, Freese auger brick machine (Mammoth Junior) of 75,000 capacity,

two Raymond represses. The brick were dried in a hot air tunnel drier

of eight tunnels, with capacity of 75,000 bricks. The fire brick molded

by hand were dried on a floor above the drier tunnels. Hot air was

forced into the drier by a large fan. The brick were burned in eight

round down-draft kilns, 28 and 30 feet in diameter, holding 40,000

blocks, and in five square down-draft kilns, holding 70,000 blocks.

The clay mine is located at the side

of the county road, over one-half mile north of the plant, and is

opened by three entries. "The fire clay and associated mottled

clays are found one mile east, by the road side and up Woodward creek,

(now Woodward Drive) and of apparently the same quality. Along this

creek is a deposit of pottery clay which has not been developed. "The

shales found on Two Mile creek and used by the Kanawha and New River

Brick Company were traced into the hills to the east near the Hannah

farm as described in an earlier section. Shales of the same horizon

were found at Barlow a few miles up Elk river, on the McDonald farm

about 80 feet above the blue clay described above, from the same farm.

|

Old photos courtesy of Steve

Fox

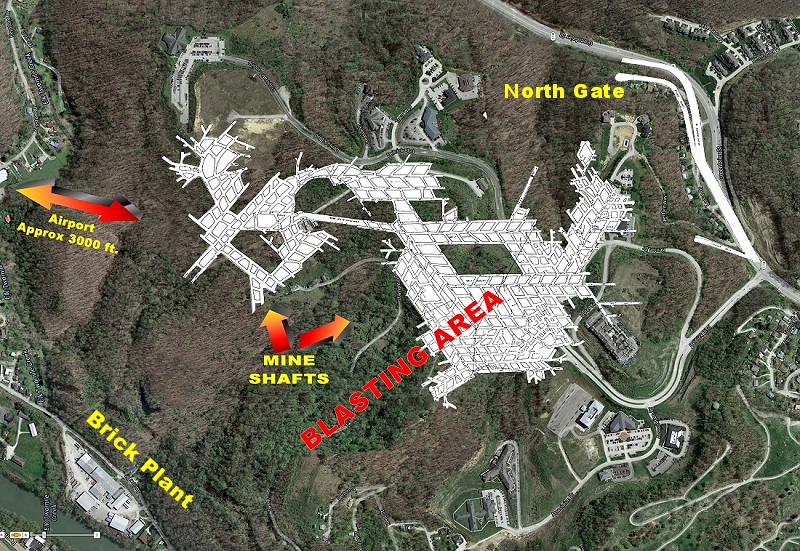

SIDE NOTE:  In

March of 2015, the end of Yeager Airports runway over-run collapsed.

It was the highest "Fill" of its type in the United States and had been in place for

years. About a year earlier, the airport authority discovered

cracks in the top of the fill. At about that same time,

contractors were blasting away at a hill in front of and slightly

to the left of the main runway in order to lower that obstacle for

takeoff. This blasting was very close to, and in some cases over

top of the clay mine shafts. Is it possible that the huge voids

underground acted like a drum, amplifying the vibrations to the airport

runway about 3000 feet away? Of course as mentioned, this was

the highest fill of its kind, and the harsh winter and then heavy

rains certainly contributed to its failure. But could the

blasting over the mines have contributed also? ( The map above is

showing the mine shafts in white, which you can see cover a large area.

This map is approximate, and not to be considered exact... but

it's very close)

Yeager Airport Overrun Collapse. Yeager Airport Overrun Collapse.

|

|

CLAYS, ROAD MATERIALS, BUILDING STONES,

Professor G. P. Grimsley in Vol. Ill of the State Geological Survey

Reports gives a general review of the clay industry in West Virginia,

along with a discussion of the origin, physical and chemical

properties, and classification of clays and their uses, to which the

reader is referred for interesting data, and the technology of the

industry. The following quotation from this volume is pertinent:

"In the Charleston region there have been a number of brick plants in

operation at various times, a number of which have been unsuccessful on

account of poor business management rather than on account of the

quality of the clays. The first brick paved street in the United States

was laid in Charleston in 1872. One block of Summers street, nearest

the Kanawha river, was paved with brick set on sand, with a

substructure of planks dipped in tar and also resting on sand. This

block is still in use, and the street at this day is in very fair

condition. For a number of years after that date, the Charleston brick

was shipped into Ohio, and the first brick paved street in Columbus in

the early 80's was laid with the Charleston brick, set on tarred planks.

"With the opening of the paving industry in Ohio, the sale of

Charleston brick was confined to the State, and in later years, they

were used mainly for local trade, very few paving brick being shipped

away. At the present time no paving brick are made at Charleston.

"Some of the best fire brick in the State were made for a number of

years on Elk river, just above Charleston, but at the present time no

fire brick are made in this vicinity. Near Charleston are located some

deposits of fire clay equal to the best in the State, and to be

favorably compared with standard fire clays of the Eastern states.

These shales and clays make paving brick of the highest quality, and

the deposits are almost unlimited. They burn both buff and red, making

fine grades of pressed and ornamental building brick. Here also occur

fine grained clays adapted to manufacture of pressed b*rick and tile,

also good stoneware clays.

"The area of these clays is large, and their location is close to the

Great Kanawha Valley coal fields, and gas fuel Is also available. Three

lines of railroads reach the field, and the Kanawha furnished water

transportation for fuel and for the finished product. With all these

natural advantages, the Charleston region should be the greatest center

of clay industries in the State, but at the present time there are only

three small yards using the river clays and one yard using the clay

mined In the hill.

"It is difficult to explain the causes of the non-development of this

field. There have been some discouraging failures in plants In this

region, but in no case have they been due in any degree to the

character of the claye. It is hoped that when the natural advantages of

this region for clay working in its different lines are fully

appreciated capital will come in to develop the field properly Clay

products should be shipped out of this territory to supply the trade

not only of West Virginia, but of the cities east, south, and even

west. A careful examination of the results of the investigation of

these clays now to be given, will show their high character, and their

location, in part. It must be remembered that the report of these

Charleston clays is not complete, and there probably exists other

important deposits that were not visited in the course of this

investigation. The clays which have been developed near Charleston

belong to the Conemaugh Series and the Upper Kanawha Series."

In Kanawha county, at this time, there are three brick plants,

manufacturing building and paving brick in the city of Charleston: The

W. Va. Clay Products Company, The Standard Brick Company and The

Kanawha Brick Company.

West Virginia Clay Products Company.

This plant was formerly the Charleston Fire Brick Company, and on pages

231-333 of Vol. III, West Virginia Geological Survey, the following

description is given:

"The plant of this company is located up Elk river two miles from

Charleston at Two Mile creek station on the Coal & Coke railroad.

It is one of the old brick yards of the Charleston region, and has been

used from time to time for the manufacture of fire brick, but it has

been idle since 1901. During that year 1,500,000 fire brick were made

for the coke ovens of the Kay Coal Company.

"The capacity of the plant is 25,000 bricks a day. The plant is

equipped for the manufacture of stiff-mud building brick, though none

has been made for some years. The equipment consists of a nine-foot dry

pan, six-foot wooden pug mill, Bucyrus auger of 30,000 capacity, Eagle

repress. The building bricks were dried in mine track tunnel drier

heated by fires below. The fire brick were dried on a heated floor

large enough to hold 10,000 brick. The building brick were burned in

one up-draft kiln, and the -fire brick in two round down-draft kilns,

26 feet in diameter, drawing into one stack.

"The river clay from a ten-foot pit near the mill was used for building

brick. The fire brick were made from a mixture of one third flint clay

and about two-thirds plastic clay from the mine on the hill back of the

plant.

"Clay Mine.—The clay is worked in an open pit one mile and a half from

the plant on Elk, and 180 feet above the level of the plant. This mine

could be reached by wagon road and the clay was formerly hauled to the

plant by this route. Later a track was built from the mine around the

hill to an incline by cable and across the railroad on raised trestle

to be dumped at the mill. This track is now in bad repair but could be

renewed at no great cost.

"The clay pit has caved along the banks and the talus covers the flint clay over much of its surface.

The Standard Brick Company.

The Kanawha and New River Fire Brick Company once manufactured brick in

Charleston, but the plant is now abandoned, as it was destroyed by fire

in 1904, and has been rebuilt as the Standard Brick Company. The

following is a short description of the original plant and mine given

in Vol. Ill, pages 229-231, W. Va. Geological Survey, 1905 :

"The plant of this company was built near the close of the year 1902,

two and one-half miles west of Charleston on the Kanawha & Michigan

railroad. The plant was a very substantial one, with a large equipment

of machinery, housed in large and well constructed buildings. The cars

were hauled from the mine by electric trolley and the buildings lighted

by electricity. It was one of the most expensive plants in the State,

but was destroyed by fire in the fall of 1904 and has not been rebuilt.

It manufactured fire brick, building brick, and a very high quality of

paving block. The destruction of the plant was a great loss to the

brick industry of the State.

"The equipment consisted of two nine-foot Stevenson dry pans, one

Martin wet pan, twelve-foot plug mill, Freese auger brick machine

(Mammoth Junior) of 75,000 capacity, two Raymond represses. The brick

were dried in a hot air tunnel drier of eight tunnels, with capacity of

75,000 bricks. The fire brick molded by hand were dried on a floor

above the drier tunnels. Hot air was forced into the drier by a large

fan. The brick were burned in eight round down-draft kilns, 28 and 30

feet in diameter, holding 40,000 blocks, and in five square down-draft

kilns, holding 70,000 blocks. These blocks were made 8%x2%x4 inches in

size.

"Clay Mine.—The clay mine is located at the side of the county road,

over one-half mile north of the plant, and is opened by three entries.

Kanawha Brick Company.

On pages 262-264 of Vol. Ill of the same report the following

description is given of the Kanawha Brick Company. A section of this

mine has already been given on page 180 of this report.

"At the plant of this company, one mile east of town on the Kanawha

river, ten feet of river clay is worked, as well as the hard clay from

the hills above. The equipment of the plant has been described in the

preceding chapter with a description of the hillside clays. The river

clay has been used since 1897 in the manufacture of red building brick

and is burned in three up-draft kilns.

"This company has another yard on 131k river, one mile from Charleston,

which was started by Mr. Isaacs seventeen years ago. The clay Is ground

in a Potts crusher, tempered in a twelve-foot pug mill and molded on an

auger machine of 40,000 capacity, making 25,000 brick daily. The brick

are dried in an eight-track steam tunnel drier, holding 72 cars, with

45,000 capacity. The brick are burned In one down-draft kiln, 28 feet

in diameter, holding 60,000, and three updraft kilns, 21 arch, holding

360,000 each, and burned with gas.

"The river clay is 15 feet thick in this pit and is hauled in cars by

cable to the plant. The first paving brick probably used In the united

States were made from the Kanawha Valley river clays at a point further

down the river, by Mr. Isaacs.

"Chemical Composition.—The clay from the Kanawha Brick Company yard on

the Kanawha river above Charleston, and the yard on Elk river were

analysed, showing the following composition:

John S. McDonald Fireclay.

Fireclay crops on the John S. McDonald farm at Barlow, in a railroad cut, about yż mile above Barlow Station.

The shales found on Two Mile creek and used by the Kanawha and New

River Brick Company were traced into the hills to the east near the

Hannah farm as described In an earlier section. Shales of the same

horizon were found at Barlow a few miles up Elk river, on the McDonald

farm about 80 feet above the blue clay described above, from the same

farm. Fifteen feet of shales are exposed to the top of the hill, with

heavy sandstone below. The horizon of these shales is that of the

Pittsburgh red shale, the same as at Morgantown.

"Both of these shales near Charleston turn red, making a high grade

building brick, and are accessible to the rail road. The McDonald shale

is only a short distance from the Coal & Coke rail road, while that

on the Hannah farm is about one-half mile from the Kanawha &

Michigan road. Neither deposit has been developed, though both have

been tested in a practical way in the local brick yards with marked

success. The analyses of these shales show a close resemblance to the

Morgantown shale, except they have a higher percentage of ferric iron

Coal and Coke Railroad Quarry at Charleston

"A large sandstone quarry was opened a number of years ago a short

distance up Elk river from Charleston to supply stone for the locks and

dams on the Kanawha river. In April 1904 the quarry was opened to

supply ballast for the railroad and has been open since that time. It

is located at the side of the Coal and Coke railroad tracks in the Elk

river bluff one mile and a half northeast of Charleston, and is

operated by the railroad company. Seventy or eighty men are employed

and 250 to 300 yards of ballast quarried and crushed daily. At the

present time no building stone is quarried.

"The floor of the quarry is about 30 feet above Elk river, and a small

coal is found near the center of the quarry which is probably one of

the Allegheny coals. This sandstone forms the upper portion of the

Charleston sandstone of Campbell, or the Buffalo-Mahoning horizon and

probably a part of the Freeport.

"The stone is rather fine grained, blue or gray in color with mica

flakes through it. It breaks readily into blocks and shows foliation in

many ledges. These plants are often curved, but the curved lines

finally disappear in the solid stone.

"The face of the quarry runs northeast-southwest at an angle of nearly

45 degrees. It is 350 to 400 feet long, and worked back 40 to 60 feet.

Patrick Ryan Quarry at Charleston.

"One mile northeast of Charleston up a ravine a short distance 'from

the Coal and Coke quarry, Mr. Patrick Ryan operates a sandstone quarry

opened 20 years ago. Ten men are employed and two or three perch of

building stone sent out daily during the working season, also 100 to

200 tons of crushed stone for concrete. Its geologic horizon is the

same as at the Coal and Coke quarry.

"The sandstone is bluish gray in color, foliated with mica flakes. Some

of the stone is banded with wavy red lines due to iron stain, giving a

variegated color. In other ledges the stone is nearly pink in color,

and the calico stone is characterized by irregular wavy bands of yellow

and red through a buff or yellowish rock. The stone readily breaks

along the mica planes or along the red streaks. The bands are often

cross bedded and more or less curved. On account of the number of bands

or planes, the stone can be split into blocks of almost any desired

thickness, building blocks, curb, or flagging.

"Quarry.—The face of the quarry runs about 45 degrees northwest, 300

feet long, and worked back 30 to 40 feet. The quarry is located on Coal

Branch, and was formerly worked on both sides of the creek.

Savage Quarry at Charleston.

"Mr. P. M. Savage operates a quarry at north end of Capitol street near

the Coal & Coke railroad and the city of Charleston. This quarry is

one of the oldest quarries near this city, and the stone is used for

buildings and crushed for concrete. Twenty to thirty men are employed,

and 150 to 200 tons of stone are crushed daily in an Austin No. 5

crusher. The stone is said to weigh about 2,700 pounds to the cubic

yard.

"This sandstone comes at the horizon of the other Charleston quarries

described above. The rock is gray or bluish gray in color with

foliation planes through it, giving a banded appearance- The bands are

frequently cross-bedded, and the stone splits readily along these

planes. In the old exposed portion of the quarry, the stone has

weathered to a buff color, and at the north end it is shaly and badly

broken on outcrop.

"Through the rock occur nodules and streaks of coal, which are

especially abundant about 20 feet from the top of the quarry down to

near the base. The cracks and joint planes are coated with a brown

discoloration which sometimes extends a few inches into the stone from

the fissure lines, and is due to Iron in percolating surface waters.

Some of the blocks tend to break with a shelly fracture, giving curved

surface to the stone. In some parts of the quarry small, round, hard,

pebbles of quartz occur, also brown chert or flint fragments.

"Quarry.—The face of the quarry runs north and south, 170 feet long

with the old workings extending 80 feet further to the south. It has

been worked back to the east 75 to 80 feet.

|

Back to index

|